Erp Software Food Industry

Welcome to a world where technology and food production intersect to create efficiency and innovation. In the fast-paced and competitive landscape of the food industry, companies are turning to ERP software to streamline operations, enhance decision-making processes, and improve overall performance. From inventory management to supply chain optimization, ERP software plays a crucial role in transforming the way food businesses operate. Let’s explore the impact of ERP software in the food industry and how it is revolutionizing the way we produce, distribute, and consume food.

Streamlining Operations in the Food Industry with ERP Software

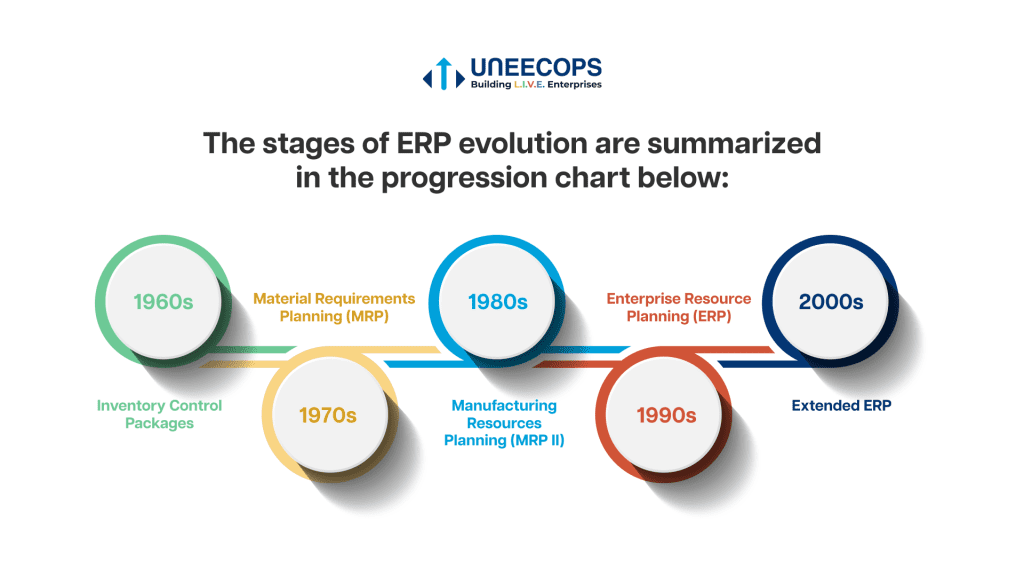

As the food industry continues to evolve and grow, the need for efficiency and optimization in operations has become increasingly important. This is where ERP (Enterprise Resource Planning) software comes into play. ERP software is a system that integrates various business processes and functions into a single platform, providing real-time visibility and control over all aspects of a company’s operations. In the food industry, this can mean everything from inventory management and procurement to production planning and distribution.

One of the key benefits of ERP software in the food industry is its ability to streamline operations. By providing a centralized platform for all data and processes, ERP software eliminates the need for manual data entry and reduces the risk of errors. This, in turn, allows food companies to operate more efficiently and with greater accuracy. For example, with ERP software, businesses can automate tasks such as order processing, inventory tracking, and production scheduling, saving both time and resources.

Furthermore, ERP software helps food companies to better manage their supply chain and procurement processes. By providing real-time visibility into inventory levels, demand forecasts, and supplier performance, ERP software allows businesses to make more informed decisions and optimize their purchasing processes. This not only helps to reduce costs but also ensures that companies have the right products available at the right time.

Another important aspect of streamlining operations with ERP software is the ability to improve collaboration and communication within a food company. By providing a centralized platform for all departments and employees to access and share information, ERP software helps to break down silos and improve overall efficiency. This can be particularly useful in large food companies with multiple locations or departments, where communication and coordination can be a challenge.

Overall, ERP software plays a crucial role in streamlining operations in the food industry. By providing a centralized platform for all data and processes, ERP software helps businesses to operate more efficiently, reduce costs, and improve collaboration. In today’s fast-paced and competitive food industry, having the right tools and technologies in place is essential to staying ahead of the curve. ERP software is one such tool that can help food companies to streamline their operations and achieve success in the ever-evolving market.

Inventory Management in the Food Industry using ERP Software

Inventory management is a crucial aspect of running a successful food business. With the fast-paced nature of the industry, having an efficient system in place to manage inventory is essential. This is where ERP (Enterprise Resource Planning) software comes into play. ERP software helps food businesses streamline their inventory processes, track stock levels, and forecast demand more accurately.

One of the key features of ERP software in inventory management is real-time tracking. With the ability to monitor stock levels and movement in real-time, food businesses can avoid stockouts and overstock situations. This helps in maintaining optimal inventory levels, reducing waste, and ensuring that products are always available for customers.

Another benefit of using ERP software for inventory management in the food industry is the ability to streamline purchasing processes. By automating the purchasing process, businesses can reduce errors, improve efficiency, and save time. With ERP software, businesses can set up reorder points and automatically generate purchase orders when stock levels reach a certain threshold. This helps in maintaining consistent inventory levels and avoiding delays in replenishing stock.

Furthermore, ERP software can help in identifying slow-moving or expired products in the inventory. With detailed reporting and analytics capabilities, businesses can easily track the performance of each product and make informed decisions on pricing or promotions. This helps in minimizing waste and maximizing profits.

Additionally, ERP software can assist in managing multiple locations or warehouses. With multi-site functionality, businesses can track inventory levels across different locations in real-time, transfer stock between locations, and optimize stock levels efficiently. This is especially useful for food businesses with multiple branches or distribution centers.

Overall, inventory management in the food industry using ERP software offers numerous benefits such as real-time tracking, streamlined purchasing processes, visibility into product performance, and multi-site management capabilities. By implementing an ERP system tailored for the food industry, businesses can optimize their inventory processes, reduce costs, and improve customer satisfaction.

Enhancing Compliance and Traceability with ERP Software in the Food Industry

Ensuring compliance with regulations and maintaining a high level of traceability are crucial aspects of the food industry. With the help of ERP software, these tasks become much more manageable and efficient.

One of the key benefits of using ERP software in the food industry is the ability to automate and streamline compliance processes. This software can help companies ensure that they are meeting all necessary regulations and standards, such as FDA regulations or food safety guidelines. By centralizing all data and processes in one system, ERP software allows companies to easily track and monitor their compliance efforts in real-time.

Furthermore, ERP software can enhance traceability in the food industry by providing detailed tracking of ingredients, suppliers, and production processes. In the event of a recall or contamination issue, having accurate traceability data can be crucial for identifying the source of the problem and taking swift corrective action. ERP systems allow for complete visibility into the entire supply chain, making it easier to trace products back to their origins.

Additionally, ERP software can help improve overall quality control in the food industry. By using integrated quality management modules, companies can set up automated quality checks and alerts to ensure that products meet the necessary standards. This can help prevent issues such as product defects or inconsistencies, ultimately leading to higher customer satisfaction and retention.

Another benefit of using ERP software for compliance and traceability in the food industry is the ability to generate comprehensive reports and analytics. These reports can provide valuable insights into areas that may need improvement or optimization, helping companies make more informed decisions and adapt to changing market conditions.

In conclusion, ERP software plays a vital role in enhancing compliance and traceability in the food industry. By centralizing data, automating processes, and providing detailed tracking capabilities, ERP systems enable companies to meet regulatory requirements, maintain high standards of quality control, and respond quickly to any issues that may arise. With the increasing focus on food safety and transparency, investing in ERP software is a smart choice for companies looking to stay competitive and compliant in the ever-evolving food industry.

Improving Decision-making with Real-time Data from ERP Software in the Food Industry

One of the key advantages of using ERP software in the food industry is the ability to access real-time data that can significantly improve decision-making processes. In a fast-paced and competitive market, having access to up-to-date information is crucial for making informed decisions that can drive business growth and success.

With ERP software, food industry businesses can gather, analyze, and visualize data from various departments such as production, inventory, sales, and finance. This data is then presented in easy-to-understand dashboards and reports, allowing decision-makers to quickly identify trends, patterns, and opportunities.

Real-time data from ERP software can help food industry businesses in several ways:

1. Inventory Management: By having real-time visibility into inventory levels, businesses can optimize stock levels, reduce excess inventory, and prevent stockouts. This can help in improving operational efficiency and reducing costs.

2. Demand Forecasting: ERP software can utilize real-time data to forecast demand accurately, helping businesses to plan production schedules, procurement, and distribution more effectively. This can lead to reduced lead times, improved customer satisfaction, and increased sales.

3. Production Planning: With real-time data on production processes and machine performance, businesses can identify bottlenecks, optimize production schedules, and improve overall efficiency. This can lead to faster turnaround times, reduced waste, and increased profitability.

4. Quality Control: Real-time data from ERP software can help in monitoring and controlling the quality of raw materials, production processes, and finished products. By analyzing data in real-time, businesses can quickly identify any deviations from quality standards and take corrective actions to ensure consistency and compliance.

In conclusion, real-time data from ERP software plays a vital role in improving decision-making processes in the food industry. By leveraging this data effectively, businesses can enhance operational efficiency, reduce costs, increase sales, and ultimately drive business growth and success. Investing in ERP software with real-time data capabilities is essential for staying competitive in the rapidly evolving food industry.

Maximizing Efficiency and Productivity with ERP Software in the Food Industry

Enterprise Resource Planning (ERP) software has revolutionized the way businesses in the food industry operate. With the advancement of technology, ERP systems have become essential tools for streamlining processes, improving efficiency, and maximizing productivity. In the food industry, where operations are complex and demand for quality and safety is high, ERP software plays a crucial role in optimizing operations and driving growth.

One of the key benefits of implementing ERP software in the food industry is the ability to centralize data and processes. By integrating various functions such as production, inventory management, procurement, sales, and financials into a single platform, ERP software eliminates the need for manual data entry and reduces the risk of errors. This centralized approach allows for better visibility and control over all aspects of the business, leading to improved decision-making and operational efficiency.

Another advantage of using ERP software in the food industry is the automation of repetitive tasks. Manual processes such as order processing, inventory tracking, and reporting can be time-consuming and prone to errors. ERP software automates these tasks, freeing up resources and enabling employees to focus on more strategic activities. By reducing manual intervention, businesses can operate more efficiently and respond quickly to changing market demands.

ERP software also helps in optimizing production processes in the food industry. With features such as demand forecasting, production planning, and recipe management, ERP systems enable businesses to streamline production schedules, reduce waste, and improve product quality. By automating production processes and providing real-time insights into production metrics, ERP software helps businesses meet customer demands efficiently while maintaining high standards of quality and safety.

Furthermore, ERP software facilitates better collaboration and communication within the organization. By providing a centralized platform for all departments to access and share information, ERP systems improve coordination between teams, leading to better decision-making and faster response times. With real-time data and analytics, employees can make informed decisions, identify bottlenecks, and take corrective actions promptly, thereby enhancing overall efficiency and productivity.

In conclusion, ERP software has become a cornerstone of success for businesses in the food industry looking to maximize efficiency and productivity. By centralizing data and processes, automating repetitive tasks, optimizing production processes, and enabling better collaboration, ERP systems empower food businesses to operate more efficiently, respond quickly to market demands, and drive growth. As the food industry continues to evolve, ERP software will play a crucial role in helping businesses stay competitive and deliver high-quality products to customers.