Manufacturing Erp For Small Business

Manufacturing ERP Solutions for Small Businesses

Welcome, fellow small business owner! Are you looking to streamline your manufacturing processes and improve efficiency in your operations? Look no further than Manufacturing ERP Solutions. These software systems are specifically designed to help small businesses like yours manage everything from inventory and production planning to customer orders and accounting. With easy-to-use interfaces and customizable features, Manufacturing ERP Solutions can help take your business to the next level. Let’s explore how these solutions can benefit your small manufacturing business.

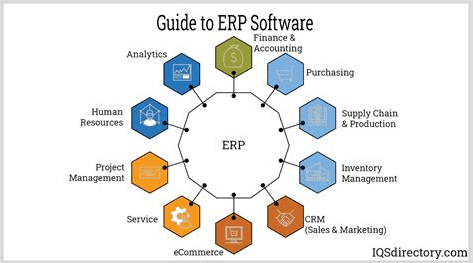

Understanding the Basics of Manufacturing ERP

Manufacturing Enterprise Resource Planning (ERP) software is a powerful tool that helps small businesses streamline their manufacturing processes. ERP systems are designed to integrate and manage all aspects of a business, from inventory control to production scheduling to customer relationship management. By using an ERP system, small manufacturers can improve efficiency, reduce costs, and increase profitability. Here are some key features of Manufacturing ERP that small business owners should be aware of:

One of the main functions of Manufacturing ERP is to help businesses manage their inventory. With an ERP system, small manufacturers can track their raw materials, work-in-progress, and finished goods in real-time. This allows them to optimize their inventory levels, reduce stockouts, and prevent excess inventory buildup. By having a clear view of their inventory status, small businesses can make more informed decisions about purchasing, production planning, and scheduling.

In addition to inventory management, Manufacturing ERP also helps small businesses streamline their production processes. ERP systems can automate workflows, track production orders, and monitor machine utilization. By optimizing production schedules and reducing waste, small manufacturers can increase their overall efficiency and output. This can result in faster lead times, higher quality products, and improved customer satisfaction.

Furthermore, Manufacturing ERP is essential for small businesses to maintain compliance with industry regulations and standards. ERP systems can track and trace materials, monitor quality control processes, and generate compliance reports. This is particularly important for manufacturers in regulated industries such as food and beverage, pharmaceuticals, and aerospace. By using an ERP system, small businesses can ensure that they meet all requirements and avoid costly penalties or fines.

Another key feature of Manufacturing ERP is its ability to provide business intelligence and analytics. ERP systems collect data from various sources within the organization and generate reports, dashboards, and KPIs. This information can help small business owners make strategic decisions, identify trends, and forecast future demand. By having access to real-time data, small manufacturers can react quickly to changes in the market and stay ahead of their competition.

In conclusion, Manufacturing ERP is a valuable tool for small businesses looking to improve their competitiveness and efficiency. By understanding the basics of Manufacturing ERP and its key features, small manufacturers can make informed decisions about implementing an ERP system in their organization. With the right ERP solution, small businesses can optimize their processes, reduce costs, and increase their bottom line.

Benefits of Implementing ERP for Small Businesses

Implementing an ERP system can provide numerous benefits for small businesses. One of the most significant advantages is improved efficiency. By centralizing all business processes and data into one platform, small businesses can streamline operations and eliminate redundant tasks. This allows employees to focus on more important tasks and ultimately increases productivity.

Furthermore, an ERP system can enhance communication and collaboration within the organization. With all departments sharing the same information in real-time, employees can make better informed decisions and work together more effectively. This can lead to improved customer satisfaction and overall business performance.

Another benefit of implementing an ERP system for small businesses is improved data accuracy. Manual data entry and paper-based processes are prone to errors, which can lead to costly mistakes. With an ERP system, businesses can automate data entry and ensure that information is entered accurately every time. This can help reduce errors, improve decision-making, and provide a more accurate picture of the business’s financial health.

Cost savings is also a significant benefit of implementing an ERP system for small businesses. By streamlining processes, reducing errors, and improving efficiency, businesses can save money on operational costs. Additionally, an ERP system can help identify areas of waste and inefficiency, allowing businesses to make informed decisions on where to cut costs and improve profitability.

Lastly, implementing an ERP system can help small businesses stay competitive in today’s fast-paced business environment. By automating processes, improving efficiency, and providing better access to data, small businesses can adapt quickly to changing market conditions and customer demands. This can help businesses grow and thrive in a constantly evolving marketplace.

Features to Look for in a Manufacturing ERP System

When it comes to choosing a manufacturing ERP system for your small business, there are several key features that you should consider in order to make the most out of your investment. Here are some important features to look for:

1. Inventory Management: One of the most important features to look for in a manufacturing ERP system is robust inventory management capabilities. This includes the ability to track raw materials, work-in-progress inventory, and finished goods inventory in real-time. The system should also have the ability to generate automatic reorder points and manage inventory levels efficiently.

2. Production Planning and Scheduling: A good manufacturing ERP system should have features that allow for effective production planning and scheduling. This includes the ability to create production schedules based on demand forecasts, lead times, and available resources. The system should also be able to provide real-time updates on the status of production processes and adjust schedules as needed.

3. Quality Control and Compliance: Another important feature to look for in a manufacturing ERP system is robust quality control and compliance functionality. This includes the ability to track quality control measures throughout the production process, such as performing inspections and tests at key points in the manufacturing process. The system should also have features that help ensure compliance with industry regulations and standards, such as FDA regulations for food and drug manufacturers.

By choosing a manufacturing ERP system that includes these key features, you can help improve the efficiency and effectiveness of your small business operations. Make sure to carefully evaluate your options and choose a system that meets your specific needs and budget constraints.

Tips for Successful Implementation of ERP in Small Manufacturing Businesses

Implementing an ERP system in a small manufacturing business can be a challenging task, but with the right strategies and approach, it can lead to significant improvements in operations and efficiency. Here are some tips for a successful implementation:

1. Define clear goals and objectives: Before starting the implementation process, it is important to have a clear understanding of what you want to achieve with the ERP system. Whether it is streamlining production processes, improving inventory management, or enhancing customer service, setting specific goals will help guide the implementation process and ensure that the system is aligned with your business objectives.

2. Get buy-in from all stakeholders: To ensure a smooth implementation process, it is crucial to get buy-in from all levels of the organization. This includes not only the management team but also employees who will be using the system on a daily basis. Involving key stakeholders from the beginning and communicating the benefits of the ERP system can help to mitigate resistance to change and increase the likelihood of a successful implementation.

3. Invest in training and support: One of the key factors in the successful implementation of an ERP system is providing adequate training and support to users. Many small manufacturing businesses may lack the resources to hire dedicated IT staff, so investing in training programs and providing ongoing support can help employees adapt to the new system and maximize its benefits. This may involve offering workshops, online tutorials, and access to a help desk for any technical issues that may arise.

4. Customize the system to fit your business needs: While off-the-shelf ERP systems offer a wide range of features and functionalities, they may not always align perfectly with the specific requirements of a small manufacturing business. Customizing the system to fit your unique processes and workflows can help to maximize its efficiency and effectiveness. This may involve working closely with the ERP provider to tailor the system to your business needs, or integrating third-party applications to address any gaps in functionality.

5. Test the system thoroughly: Before fully implementing the ERP system, it is important to conduct thorough testing to identify and address any issues or errors. This may involve running simulations, performing data migration tests, and conducting user acceptance testing to ensure that the system meets your business requirements and functions as intended. Identifying and resolving any issues during the testing phase can help to prevent costly disruptions once the system is live.

By following these tips and best practices, small manufacturing businesses can increase the likelihood of a successful ERP implementation and reap the benefits of improved efficiency, productivity, and competitiveness in today’s rapidly changing business environment.

Case Studies of Small Businesses that have Successfully Integrated ERP

Implementing an ERP system can greatly benefit small businesses by streamlining operations, improving efficiency, and providing valuable insights for decision-making. Here are some case studies of small businesses that have successfully integrated ERP:

1. Smith’s Furniture Store

Smith’s Furniture Store, a local family-owned business, decided to invest in an ERP system to help manage their inventory, sales, and customer data. By centralizing all their information in one system, they were able to see real-time updates on inventory levels, track customer orders more efficiently, and even personalize marketing strategies based on customer preferences. As a result, Smith’s Furniture Store saw a significant increase in sales and customer satisfaction.

2. Johnson’s Manufacturing Company

Johnson’s Manufacturing Company, a small production facility, implemented an ERP system to improve their production process and inventory management. With the ERP system, they were able to automate scheduling, monitor equipment maintenance, and track raw materials more effectively. This led to a decrease in production costs, reduced wastage, and ultimately increased profitability for Johnson’s Manufacturing Company.

3. Mary’s Boutique Fashion

Mary’s Boutique Fashion, a clothing retail store, integrated an ERP system to streamline their sales, inventory, and customer management processes. With the ERP system, they could easily track popular styles, monitor inventory levels in real-time, and analyze customer purchasing patterns. This allowed Mary’s Boutique Fashion to optimize their inventory, offer personalized promotions to customers, and ultimately increase sales and customer loyalty.

4. Joe’s Automotive Repair Shop

Joe’s Automotive Repair Shop, a small independent garage, adopted an ERP system to help manage their appointments, inventory, and financials. The ERP system allowed them to schedule appointments more efficiently, track spare parts inventory, and generate accurate financial reports. By having a better overview of their operations, Joe’s Automotive Repair Shop was able to provide quicker service to customers, reduce overhead costs, and improve their overall profitability.

5. Sarah’s Home Decor Co.

Sarah’s Home Decor Co. is a small business that specializes in handmade home decorations. They decided to implement an ERP system to help manage their supply chain, production process, and customer orders. By using the ERP system, they were able to streamline their production schedule, track the status of each order, and manage their suppliers more effectively. This resulted in faster turnaround times for customer orders, reduced production delays, and improved overall customer satisfaction. Sarah’s Home Decor Co. was able to grow their business and expand their product offerings, thanks to the successful integration of the ERP system.

These case studies demonstrate how small businesses can benefit from implementing an ERP system. By centralizing their data, automating processes, and gaining valuable insights, small businesses can improve their operations, reduce costs, and ultimately achieve greater success in the competitive market.